With the widespread application of computers, most enterprises have begun to use computer data systems to manage warehouse management data. However, data is still collected and statistically organized using the traditional method of paper records followed by manual input into the computer. This not only results in a waste of manpower resources but also leads to slow data entry speeds and low accuracy due to human factors. As enterprises continue to expand, the variety and quantity of materials in warehouse management are increasing, and the frequency of inbound and outbound operations is increasing dramatically. Warehouse management operations have become extremely complex and diversified. The traditional manual warehouse operation mode and data collection methods are difficult to meet the rapid and accurate requirements of warehouse management, severely affecting the operational efficiency of enterprises and becoming a major obstacle to their development.

Therefore, we developed a solution for RFID warehouse inventory management.

1. Log in to the website (http://39.98.246.124/)>>Username (admin)>>Password (admin)>>Log in.

1. Product details

Log in to admin account>>Product Management>>Product Details>>Add.

2. Product details operation

Product Details Action>>Add Product>>OK.

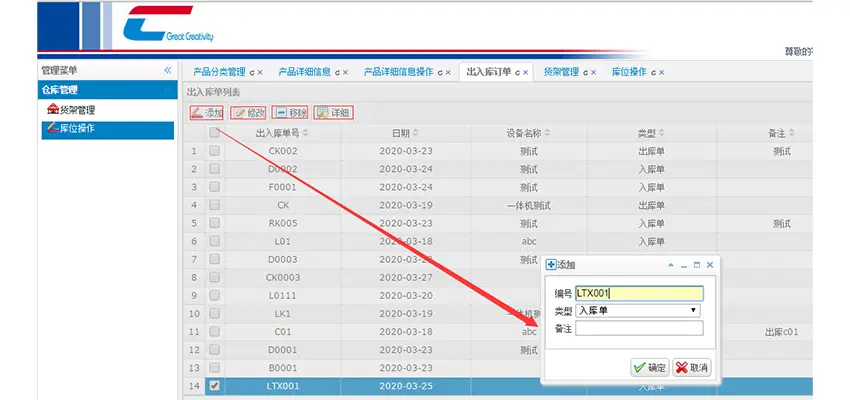

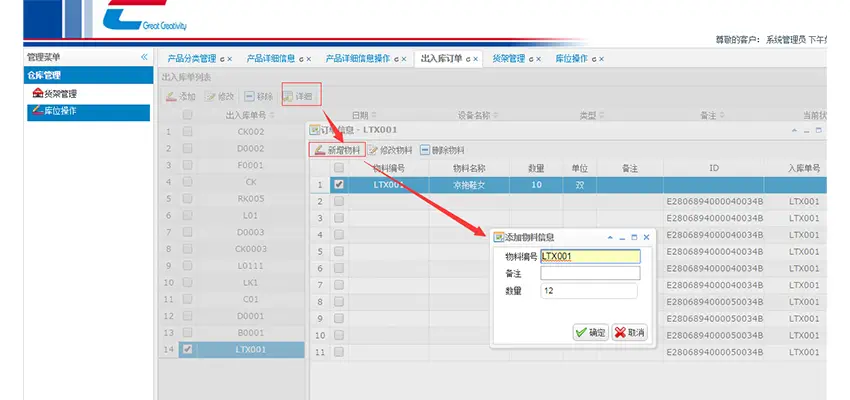

3. Inbound and outbound orders

Inbound and outbound order>>Add product>>Confirm

After adding products to and from the warehouse, select the product

Click "Details">>Add material information and confirm

1. Warehouse Management >> Shelf Management >> Add, Remove, Modify >> OK.

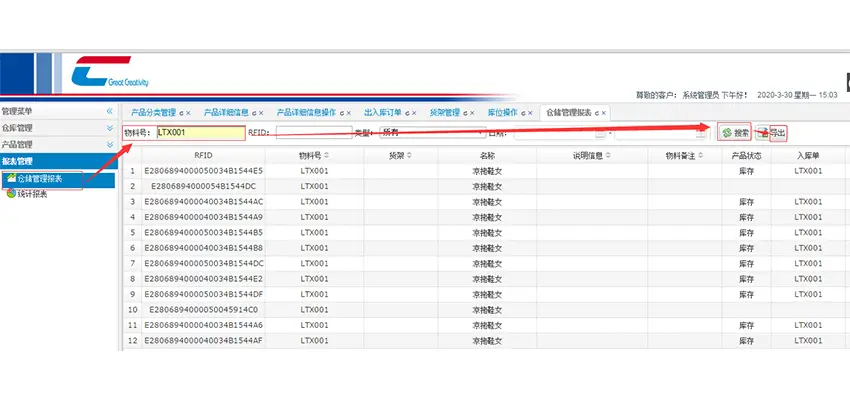

Report Management>>Warehouse Management Report>>Comfortable Material Number>>Search>>Export

Statistical report>>Enter material number>>Search>>Export>>Confirm

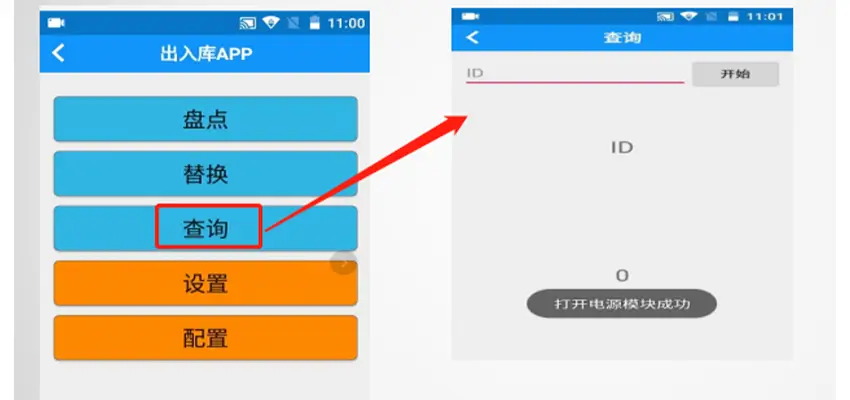

All the above operation steps are for the final "inventory". The "inventory" is done through the handheld machine, as shown below: The goods that have been counted are displayed as "green" and the goods that have not been counted do not change color.

Replacement: Enter the EPC of the original label and the EPC of the new label in the original ID and new ID boxes, click "Replace", and click "Yes" when the prompt message appears to replace the label of this product. If the network is normal, it will display "Replacement Successful"; if the original ID does not exist, it will prompt "The old ID you entered is wrong and the replacement failed"; if the new ID already exists, it will prompt "The new ID you entered already exists and the replacement failed". , when the network is not connected, the warehouse list cannot be loaded and the prompt "Network error, replacement failed" is prompted.

Query: Enter the EPC to be queried in the ID box and click the "Start" button. If the corresponding tag is read, the number of reads will be displayed below. If the tag is not read, "0" will always be displayed.

Settings: Same as the sample program, various RFID configurations can be modified.

Configuration: Enter the server address and click "OK" to modify the server to which the APP is connected.

The necessity of RFID warehousing inventory management lies in its ability to realize automated data collection, real-time monitoring and tracking, improve warehousing operation efficiency, prevent theft and losses, and optimize inventory management processes, thereby improving the company's operational efficiency and management level.

-------------------

CONTACT US

Email: info@rfidsilicone.com

Skype: live:cxjrfid

WhatsApp: +8613612933572

Website: www.rfidsilicone.com