In the fast-paced world of business, keeping track of assets efficiently is crucial for maintaining smooth operations. Whether it's equipment, inventory, or even personnel, having accurate and real-time information about the location and status of assets can make all the difference in optimizing processes and reducing costs. One technology that has revolutionized asset tracking in recent years is Radio Frequency Identification (RFID).

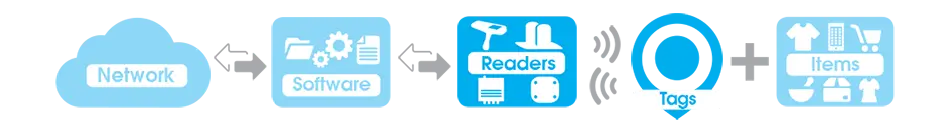

RFID is a technology that uses radio waves to identify and track objects wirelessly. RFID asset tracking involves attaching RFID tags to assets and using RFID readers or scanners to capture data stored on these tags. Unlike traditional barcode systems, RFID does not require line-of-sight scanning, making it faster and more efficient for tracking multiple assets simultaneously.

RFID Readers: Also known as RFID scanners or interrogators, these devices emit radio waves and capture data from RFID tags within their range. RFID readers can be stationary or handheld, and they come in various forms, including fixed readers installed in doorways or gates, and mobile readers used for inventory management.

RFID Middleware: This software acts as a bridge between RFID readers and enterprise systems, such as inventory management or asset tracking software. It collects data from RFID readers, filters and processes it, and then integrates it with the organization's existing systems for further analysis and decision-making.

RFID Software: This software manages and interprets the data collected from RFID tags and readers. It provides functionalities such as asset location tracking, inventory management, real-time monitoring, and reporting. RFID software can be customized to suit the specific needs of different industries and applications.

Improved Efficiency: RFID asset tracking eliminates the need for manual data entry and reduces errors associated with traditional tracking methods.

Cost Savings: By optimizing asset utilization and minimizing losses or theft, RFID can lead to significant cost savings over time.

Enhanced Security: RFID tags can be encoded with encryption and authentication features, making it difficult for unauthorized personnel to tamper with or counterfeit asset data.

Passive High-Frequency (HF) Tags: These tags operate at frequencies around 13.56 MHz and are commonly used for asset tracking in environments such as warehouses, healthcare facilities, and retail stores. They have a shorter read range compared to UHF tags but offer better performance in environments with high levels of metal or liquid.

Passive Ultra-High-Frequency (UHF) Tags: UHF tags operate at frequencies between 860 MHz to 960 MHz and are widely used for asset tracking in industries such as logistics, manufacturing, and retail. They offer longer read ranges and faster data transfer rates compared to HF tags, making them suitable for tracking assets over longer distances and in bulk.

Active Tags with Replaceable Batteries: These tags contain an internal power source (e.g., battery) and typically operate at UHF frequencies. They offer longer read ranges and are suitable for tracking high-value assets over large areas.

Active Tags with Non-Replaceable Batteries: Similar to tags with replaceable batteries, these tags have an internal power source but with non-replaceable batteries. They are commonly used for tracking assets in industries such as transportation and logistics.

Also known as battery-assisted passive (BAP) tags, these tags have a small battery that powers certain features (e.g., sensors) while relying on RFID readers for communication. They offer extended read ranges compared to passive tags and are suitable for tracking assets in challenging environments.

RFID inlays consist of an RFID chip (IC) attached to an antenna, and they can be embedded into various materials such as labels, stickers, or packaging. Inlays are versatile and can be customized to suit specific asset tracking requirements.

These tags are specifically designed to be attached to metal surfaces, which can interfere with RFID signals. They typically utilize specialized antenna designs or foam spacers to improve performance when attached to metal assets.

Some RFID tags are designed for specific use cases, such as ruggedized tags for outdoor environments, temperature-resistant tags for cold chain management, or tamper-evident tags for security applications.

Characteristics: LF RFID operates at a relatively low frequency and typically has a short read range of up to a few centimeters. It is less affected by environmental factors such as metal or water, making it suitable for applications where proximity-based identification is sufficient, such as access control systems, animal tracking, and keyless entry systems.

Characteristics: HF RFID operates at a higher frequency than LF RFID, offering a longer read range of up to several meters. It is commonly used in applications such as contactless payment systems, library book tracking, asset management, and ticketing systems. HF RFID is also compatible with Near Field Communication (NFC) technology used in smartphones and other consumer devices.

Characteristics: UHF RFID operates at a much higher frequency than LF and HF RFID, providing a longer read range of several meters to tens of meters. It is widely used in supply chain management, inventory tracking, logistics, and retail applications due to its ability to read multiple tags simultaneously and its fast data transfer rates. UHF RFID is also commonly used for vehicle identification and toll collection systems.

Characteristics: Microwave frequency RFID operates at even higher frequencies than UHF RFID, offering extremely long read ranges of up to several hundred meters. It is used in specialized applications such as vehicle tracking, container tracking, and long-range access control systems. Microwave frequency RFID requires more sophisticated infrastructure and is less common compared to LF, HF, and UHF RFID.

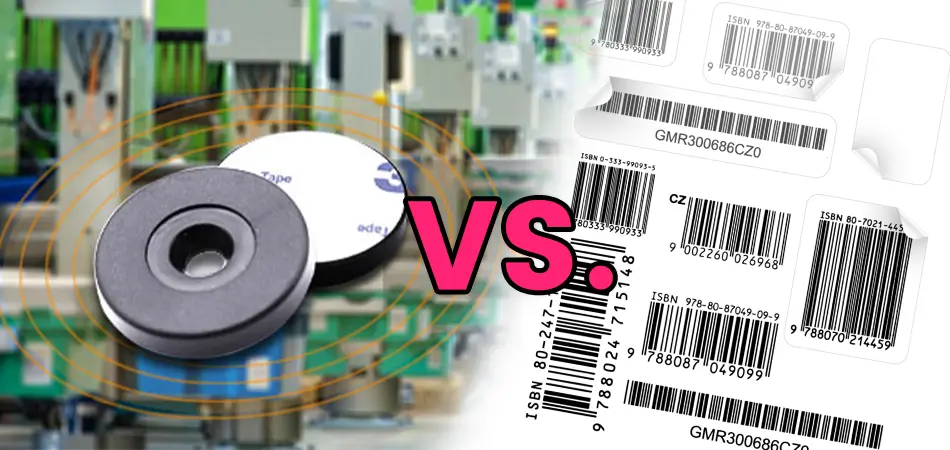

Contactless Reading: RFID tags can be read without direct line-of-sight, allowing for faster and more convenient asset tracking compared to barcodes.

Multiple Tag Reading: RFID readers can simultaneously read multiple tags within their read range, enabling batch scanning and high-speed inventory management.

Durability: RFID tags are more durable than barcode labels as they are not susceptible to wear and tear from scanning, making them suitable for harsh environments.

Longer Read Range: Depending on the frequency used, RFID tags can be read from several centimeters to several meters away, allowing for greater flexibility in asset tracking applications.

Data Storage: RFID tags can store more information than barcodes, including unique identifiers and additional data such as maintenance history or expiration dates.

There are line-of-sight requirements for using barcodes. Barcodes must be directly visible to the scanner, requiring manual scanning and limiting scanning speed and convenience. Barcodes have limited data storage capacity compared to RFID tags and typically contain only a string of alphanumeric characters. And barcodes can be easily damaged or blurred, affecting readability and requiring regular maintenance.

Retail: Tracking inventory levels, reducing shrinkage, and improving supply chain visibility.

Manufacturing: Managing work-in-progress inventory, tracking tools and equipment, and ensuring compliance with quality standards.

Healthcare: Monitoring medical equipment, tracking patient flow, and managing inventory of pharmaceuticals and supplies.

Logistics and Transportation: Tracking shipments, optimizing routes, and improving warehouse management.

RFIDSilicone smallest RFID tag is ideal for RFID tracking solutions for small tools, precision instruments, pharmaceutical reagents, surgical instruments, electronics, weapons and other metal items.

RFIDSilicone supports customization of RFID tags, RFID NFC cards, RFID wristbands, etc. You can contact us anytime!